| ||

|

|

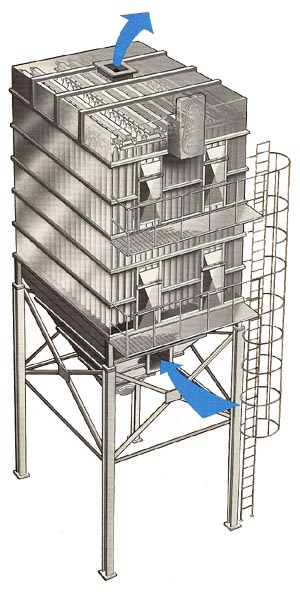

SHAKER DUST COLLECTOR TYPE CT |

|

Continuous development has resulted in CARBO-Tech's present shaker collector design. The CT collector is acknowleged as an industry leader. |

| In use dust laden gas enters the hopper thruogh a baffled inlet and passes through holes in a cell plate. The dust is collected on the inside of the bags and cleaned gas passes through the bags and out of the dust collector top. When pressure drop reaches a pre-set level, the flow of gas to the dust collector is stopped by shutting down the fan. The bags are then mechanically shaken by an eccentric drive shaker mechanism. After shaking, there is a settling period to allow the dust to settle into the hopper, after which the fan is started and gas flow resumes. For use in a continuous operation, two or more modules are arranged in parallel. When the overall pressure drop reaches a pre-set level, individual modules are isolated by closing an outlet damper and cleaned. In some applications, bag cleaning can be further enhanced by the use of a vented outlet damper which directs air from an outside air supply while gas flow through the outlet is shut off. Single CT collectors can handle 500 to 30,000 cfm, while multimodule installations can handle almost any air volume. Typical Applications |

|

|