| ||

|

|

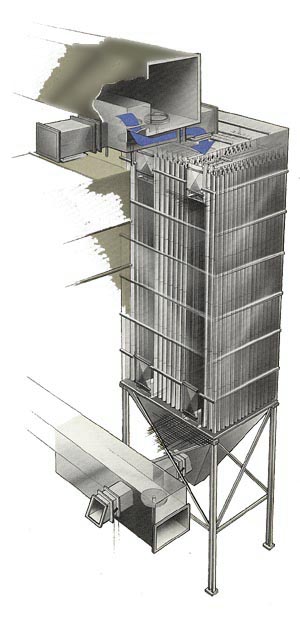

REVERSE AIR TYPE RA |

|

The CARBO-Tech Type RA Reverse air dust collector is used by industries on many large applications. Dust laden gas enters the hopper and passes through holes in a cell plate to the inside of the bags where dust is collected. Cleaned gas passes through the bags and out the top of the dust collector. At set intervals, either by timing or pressure drop, the bags are cleaned. This is done automatically, isolating one module at a time, by closing an outlet damper. After a settling period the reverse air damper opens, allowing cleaned gas from the outlet plenum to back-wash the bags. The reverse air dislodges dust from the bags allowing it to drop into the collector hopper. The reverse air damper then closes and the outlet damper opens. Cleaning can then be repeated or set to move automatically to the next module. |

|

The drawing indicates the collector in reverse air cleaning mode, with the outlet damper closed and with both the reverse air and inlet dampers open. To ensure that all available reverse air is used for cleaning, the outlet damper must not allow any leakage during the cleaning cycle. For this reason poppet or plate type dampers are used. Reverse air leaving the module re-enters the inlet plenum and is redistributed amongst the remaining modules. Typical ApplicationsBoilers and steam generators (all fuels) |

|

|