| ||

|

|

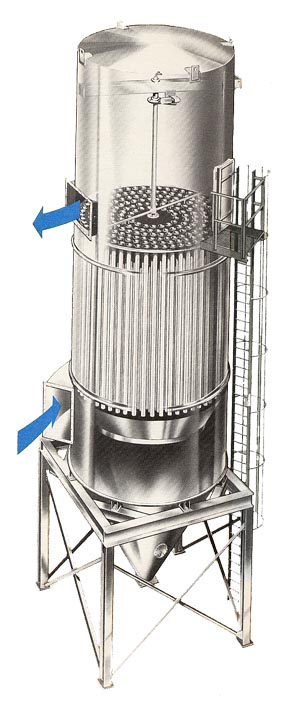

MEDIUM PRESSURE PULSE TYPE 15P |

|

The Type 15P Fabric filter dust collector uses low pressure air supplied by a blower for pulse cleaning. The cyclonic inlet acts as a pre-cleaner to knock out large sized or aero-dynamically unstable dust particles. |

| In operation, dust laden gas enters the cyclonic inlet where pre-cleaning and separation takes place. The gas then descends around a cyclonic collar where straightening vanes remove spin from the gas allowing it to flow upward. As with the Type 90P dust collector, dust is deposited on the outside of the bags and cleaned gas exits the top of the bags into the clean air plenum. An air pump or blower continuously supplies air to a header at 10 to 15 psi. The header, in turn , supplies one or two large diaphragm valves which release bursts of pulse cleaning air to a slowly rotating pulse blow pipe. This pipe rotates over the radially arranged bags and the bags are cleaned continually. Use of the air pump removes the need for a source of high quality compressed air, which makes the 15P suitable for remote locations. Units are available with walk-in plenums or roof top doors. Typical ApplicationsCoal Handling systems |

|

|