| ||

|

|

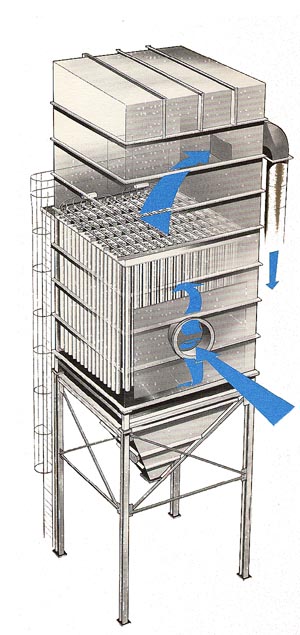

HIGH PRESSURE PULSE TYPE 90P |

|

The model 90P is the finest state of the art high pressure pulse fabric filter available today. This dust collector is used extensively in a wide range of applications, for many varied processes. |

|

Dust-laden gas enters the dust collector either into the hopper, through a double perforated plate or through a baffled side inlet, depending on dust concentration and characteristics. As the gas flows up and through the bags, dust is deposited on the outside. Cleaned gas then passes through the open top of the filter bag into a clean air plenum. Periodically a row of bags is pulsed with a reverse jet of high pressure air, dislodging collected dust which then falls into the hopper. The sequential cleaning cycle is initiated either on a timed basis or by pressure differential. The 90P dust collector is available in single or multimodule installations, single modules are capable of handling 500 to 50,000 cfm. By the use of multimodule installations, this style of collector can be designed to handle much larger process gas volumes. The 90P dust collector can be constructed of carbon steel or other alloys for gas conditions of up to 500oF and pressures as required. For extensive pressure conditions, circular designs are available. The standard 90P dust collector uses a snap type bag attachment for easy bag installation and removal. The bag support cage has an integral wide throat air inductor to aid bag cleaning. Top bag removal designs are available with either walk in plenums, hinged or lift-off roof doors. Bottom bag removal designs are also available, as well as trough or pyramidal hoppers. Typical Applications |

|

|