| ||

|

|

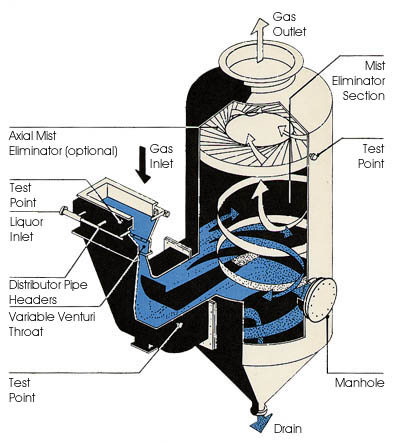

HIGH ENERGY VENTURI TYPE VS |

|

The Type VS scrubber is particularly useful for scrubbing fine submicronic particulate matter. It includes a wetted-wall inlet section to prevent wet/dry junctions and a variable throat section to maintain optimum effiency at varying gas flow rates. Throat operation can be manual or automatic. The equipment can handle recycled streams of thick and viscous slurries containing up to 15% solids. In operation, liquor is introduced by a multiple distributor pipe system. Pipes are arranged to provide complete coverage of the throat and wall washing by the liquor. Dirty gas and liquor converge at the throat entrance where extreme agitation and turbulence atomizes the liquor and mixes it with the gas. Dust and fume particles are captured by direct impingement. The resultant droplets are further agglomerated and fall to the scrubber base. The gas passes through a mist eliminator where complete removal of entrained droplets takes place. The unit can be combined with either a tray (TS) type scrubber or a packed bed (PT) type scrubber for both particulate and acidic fume removal. |

| High energy venturi scrubbers can be constructed from carbon steel, stainless steel, specialty alloys or plastics. Units are available with capacities ranging from 600 to 200,000 cfm. Typical ApplicationsExaust gas cleaning in: |

|

|